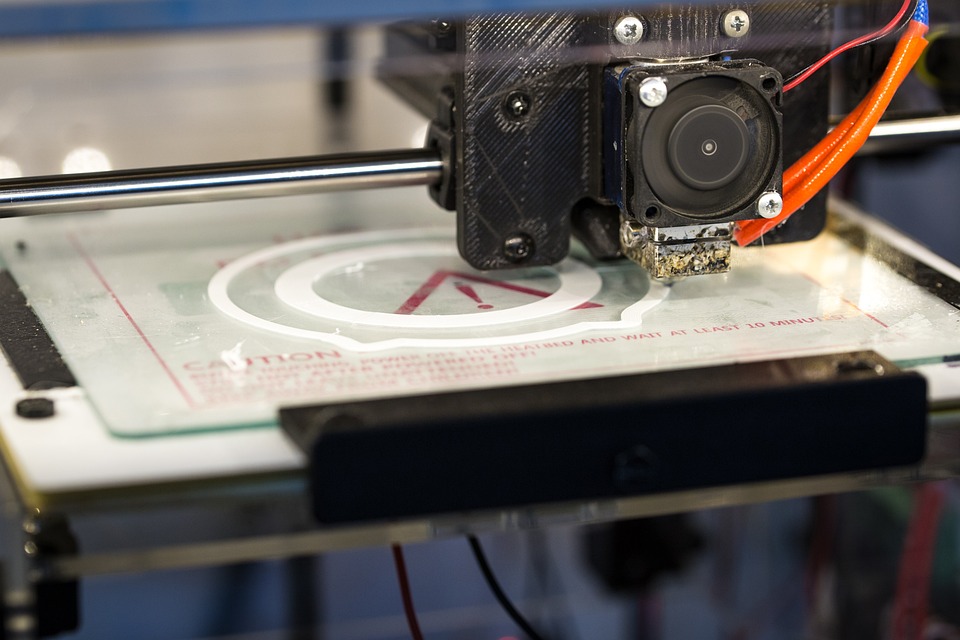

The resin-based 3D printing Sydney industry is utilizing digital light processing techniques or DLP, although stereolithography or SLA is increasingly becoming more common, too. More importantly, it is getting cheaper by the day, making it a more practical option for many industries and businesses alike.

The aesthetic side of resin prints is most of the time fantastic, hence they have gained good traction in almost every industry and became an in-demand option for industrial printing. So, when is it the right thing for us to say that moving to these cheap resin 3D printing machines make sense? To get to the bottom of this question, we need to ponder on the following points:

The output or the work done by 3D resin printers, alongside the printing process itself, is not at all comparable to the filament-type printing systems. Some important aspects such as pre-processing work, design considerations, and the post-processing side are all very distinct from each other.

Resin 3D printing takes on a different workflow instead. It brings along some consumables and hidden costs that are beyond the resin refills cost. Things may not be like how they used to be where FDM or fused deposition modeling printers were a couple of years ago at a time that we were so astounded with the quality that one printer could bring for about $200. Without a doubt, this is now far more accessible to every one of us than ever before.

3D resin printing will make sense when you have any of the following conditions.

- Build volume will likely constrict you to work only on relatively small-sized objects.

- Handling, preparation, and maintenance can be shambolic of sorts. It may even necessitate you to make use of gloves. And since some resin exudes fumes, proper and good ventilation in your workspace is a must.

- Consumables are not confined to just alcohol (to be used for part washing) and the resin. The tank build surface needs to have a replacement from time to time. If you are doing it out of passion or hobby, it is a thin plastic film very much comparable to that of the skin of a drum.

- The resin setup and cleanup work must be carried out no matter what the size of the project is. It is pretty much more practical to carry out your 3D printing jobs in batches as opposed to just one-offs, which most of the time are few and far between.

- One downside to resin material is they tend to have a shorter or limited amount of shelf life. So, therefore, if you are planning to make a stock of your resin in your build tank, never think of doing so. Otherwise, you are running the risk of having it expire on you. Therefore, you need to consume it sooner rather than at a later time.

- Resin printing comes with a higher post-processing load. This comes in the form of additional curing work, part washing, and support removal.

They all signify that resin printing comes with several hidden costs beyond the price of a bottle of resin and the 3D printing Sydney machine itself. If you don’t find them as something you should object to and you think they are pretty much acceptable for you, then there is nothing to stop you from taking advantage of the economic gains that come with desktop resin printing.

You can commence your experimenting as soon as you want. Since the resulting prints are likely going to come out well, the odds that they will look awesome is high.

Just bear this thing in mind. There is no chance that your filament-based printer machine should be taking the place of your resin printer or vice versa. Both printing systems are distinct from each other, therefore they are good at different things.