The clinical sector is the most sophisticated in how new therapies and procedures have been created. As well as the modern tools that drive all this ahead. There has been no shortage of miracles, and that continues to occur. Now, 3D printing in health care is coming, too.

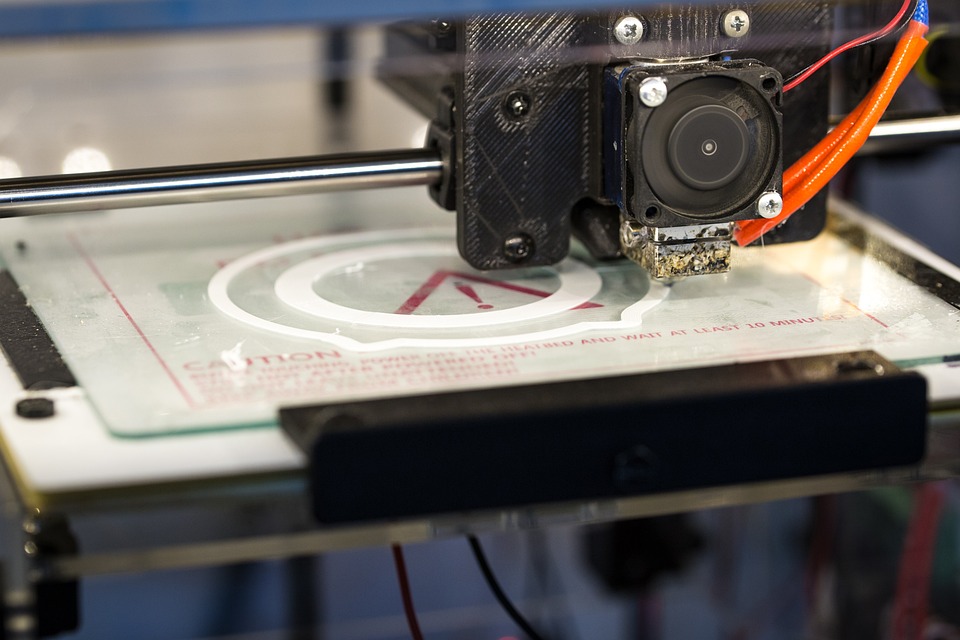

Among how the clinical market has been enhanced and improved is using 3D printers. Three-dimensional printing in medical care makes it feasible for physicians to supply people with a new type of treatment in various means. 3D printing is utilized to develop new surgical drills and cutting overviews, prosthetics, and the formation of patient-specific reproductions of organs, bones, and blood vessels.

Current advancements of 3D printing in medical care have brought about lighter, healthier, and more secure items, reduced lead times, and lower expenses. Personalized components can be customized to every individual. This boosts individuals’ understanding by medical experts and enhances client convenience degrees by permitting communication with products designed specifically for their makeup.

Usual Applications of 3D Printer Brisbane in Healthcare

Learning

While the emphasis has been on 3D printing medical gadgets and implants gadgets made use of by individuals, among the largest application areas is the construction of anatomical replicas. Physicians are currently using designs produced by a 3D printer Brisbane from individual scan information to improve the analysis of ailments, clear up therapy decisions, strategy, and, in many cases, even practice picking surgical treatments in advance of the actual treatments.

The models enable medical professionals to understand individual composition that is hard to envision, especially when utilizing minimally invasive strategies. Models additionally assist in specifically sizing clinical devices. Doctors could also use the versions to describe a forthcoming medical process to patients and their families and connect the surgical methods to their associates.

Surgical Tools

Doctors make use of devices to assist in a surgical procedure. These were traditionally constructed from titanium or lightweight aluminum. With 3D printing in medical care, physicians can produce tools that precisely adhere to a person’s distinct anatomy. 3D published tools are utilized to make the positioning of restorative therapies (screws, plates, and implants) a lot more precise, leading to far better postoperative findings. The FDM 3D printing modern technology is ideal for repetitive, low-cost prototyping to optimize a tool’s layout.

Prosthetics

Substitute or changes could be time consuming and pricey. Since prosthetics are such personal things, each one must be custom-made or fit to the wearer’s requirements. 3D printing altered all this and is currently regularly to create individual specific prosthetics components that match completely with the user’s makeup.

Indeed, technology keeps on improving and the good news is, the healthcare industry is greatly benefiting from such technologies.